protecting what matters

When it comes to protecting our public infrastructure, especially schools, every decision matters. That was the mindset driving a recent retrofit project at an elementary school in Matthews, North Carolina. With help from Charlotte Backflow and the Reitzel Corporation, Aalberts integrated piping systems provided a critical solution to upgrade the school’s aging backflow prevention system with a smarter, safer, and more efficient alternative.

the problem: aging infrastructure and flood risk

The existing backflow preventer, installed in 1991, had failed inside the building, located dangerously close to high-voltage electrical panels. After another local school had recently suffered weeks of closure due to flooding from a fire sprinkler failure, the school system was not willing to take any chances. The proposed replacement from another manufacturer could potentially discharge 250–300 GPM during relief events, an unacceptable risk given the limited drainage near the electrical area.

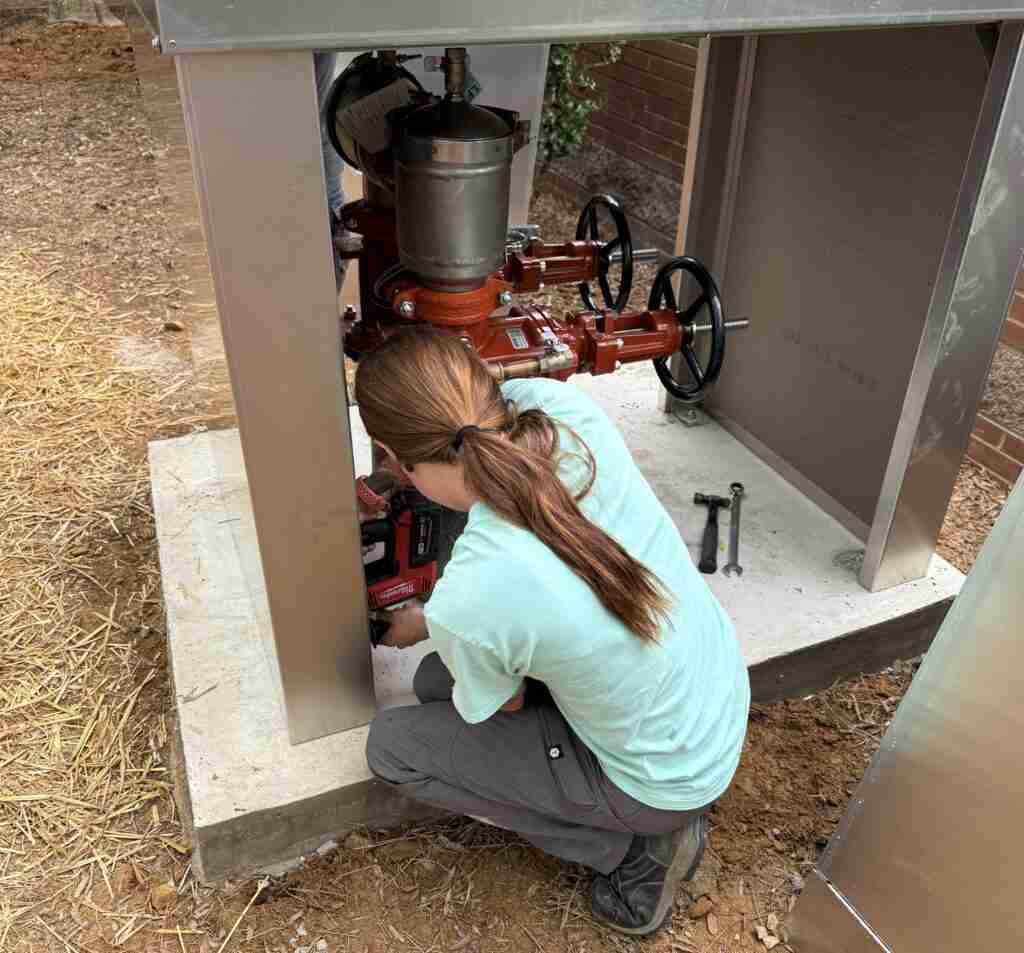

the "Apollo"® solution: safer design, faster install

That’s where our Apollo® backflow system came in. With safety and speed as the top priorities, the Reitzel team recommended moving the new backflow preventer outdoors, eliminating the risk of indoor flooding entirely. The “Apollo”® setter system was the ideal choice for the retrofit thanks to its: modular, two-piece design, mechanical joint connections, “Apollo”® RPLF4AN backflow preventer

modular, two-piece design

- the ability to separate the setter into inlet and outlet halves allowed the installation team to quickly maneuver around the existing 4” Schedule 40 PVC water line without extensive cutting or rework

mechanical joint connection

- our MJ connections are compatible with ductile iron, C900 plastic, and PVC piping, making field adaptation faster and reducing the need for additional fittings

- installed above ground using ductile iron standpipes, this reliable unit offered the right protection without the oversized discharge risks of competitor models

Thanks an efficient team, the full excavation, installation, and restoration of water service took less than four hours.

an American manufactured solution

Beyond the technical advantages, Reitzel also highlighted factors that helped win the project:

- 5-Year warranty – a level of confidence many competitors can’t match

- made in the USA – a key factor for public institutions, especially when federal funds are involved

- local availability – our products are stocked and accessible, meaning shorter lead times and faster turnaround

a model retrofit

This project demonstrates how thoughtful planning, contractor expertise, and the right product offering can come together to solve a complex problem simply. By moving the assembly outside and using the “Apollo”® flexible setter system, the Reitzel team was able to deliver a safe, efficient, and code-compliant solution that protects the school, and its students, for years to come.

At Aalberts integrated piping systems Americas, we’re proud to support retrofits like this with products that make installations faster, safer, and smarter. Whether you’re working on a school, hospital, or commercial property, we’re here with the knowledge, tools, and support to help you do it right.