fire safety starts with engineering you can trust

In today’s industrial world, safety is not optional – it’s a responsibility. At Aalberts integrated piping systems Americas, we understand that every component in a critical piping system must perform flawlessly, even under extreme conditions. That’s why our “Apollo”® valves are engineered and certified to meet API-607 fire-safe standards, ensuring reliable performance when it matters most.

what is API-607?

The API-607 standard, developed by the American Petroleum Institute, defines the fire-testing requirements for quarter-turn valves like ball and butterfly valves. It measures a valve’s ability to maintain a tight seal before, during, and after exposure to direct fire.

When a valve passes this test, it proves that it can minimize leakage even after non-metallic sealing elements—such as PTFE or elastomers—are damaged by high heat. Secondary seals, including graphite or metal-to-metal contact, automatically activate to maintain containment and safety.

The result is continued system integrity, valuable response time, and protection of people, property, and the environment.

why fire-safe valves matter

During a fire, standard valves can quickly fail, allowing hazardous fluids or gases to escape. This increases risk, damages equipment, and can endanger lives. API-607 fire-safe valves provide:

backup sealing protection when primary seals fail

compliance with industrial safety standards and regulations

peace of mind for engineers, contractors, and facility operators

In industries such as oil and gas, chemical processing, and power generation, fire-safe certification isn’t optional-it’s required by code or project specification.

87A & 88A flanged ball valves

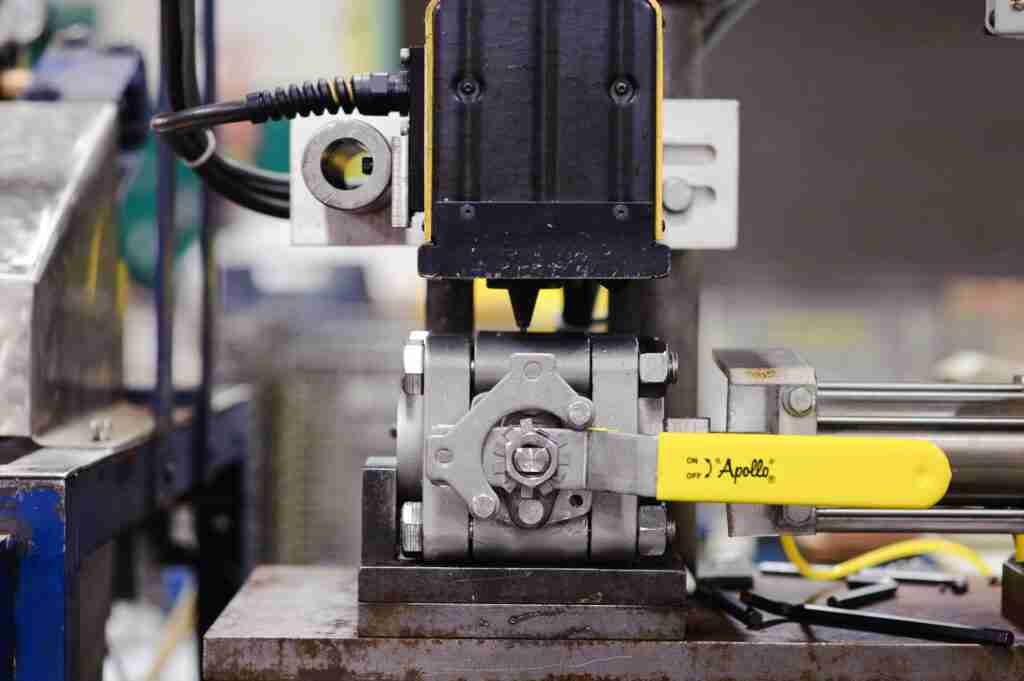

83A three-piece ball valves

Designed for durability with a carbon steel body and stainless trim, these full-port valves include a swing-out center section for easy maintenance and a fire-safe design for dependable performance.

vacuum service to 29″ Hg

steam rating: 150 psi

applications: vacuum, compressed air, steam, cooling, heating

215L & 230L high-performance butterfly valves

Aalberts IPS: built beyond compliance

Advancements in pressure reducing valve (PRV) technology increasingly focus on environmental sustainability by optimizing energy use and minimizing system leaks. Modern PRVs enhance system efficiency, reducing the energy required for operations and decreasing carbon emissions. Additionally, improved materials and design reduce leak risks, conserving resources and preventing environmental contamination.

the bottom line

Choosing API-607 fire-safe valves means preparing for the unexpected and protecting what matters most. Aalberts IPS is proud to deliver engineered solutions that perform under pressure – even in the most critical conditions.