sustainable entrepreneurship

we engineer mission-critical technologies enabling a clean, smart and responsible future

we enable our stakeholders to move forward sustainably

we see sustainability as a business opportunity and use it as a growth driver, that is why we rather call it sustainable entrepreneurship.

we are driven by four global tailwinds, prompting structural shifts in our industries

sustainability for all stakeholders

sustainable

entrepreneurship

At Aalberts, we engineer mission-critical technologies enabling a clean, smart and responsible future. We strive to unleash the full potential of the environmental and societal impact of our technologies, to leverage current global tailwinds and to support our customers in their sustainability journey. While we are dedicated to deliver on our own commitments to be net zero carbon by 2050, use natural resources as efficient as possible and reduce water use, we continue to focus on the positive impact of our technologies for our customers.

We call this the multiplier effect. By engineering products and services that enable our customers to enhance their own business and save resources, we help them reducing CO₂ emissions throughout the lifecycle of their operations. This is how we amplify sustainability, not just by improving what we do, but by empowering others to reduce their environmental footprint. These solutions ripple across industries, driving meaningful change beyond what we could achieve alone. That is how we make an impact, by working together in the value chain and through innovation that serves both our customers and the planet.

we are driven by four global tailwinds, prompting structural shifts in our industries. Driven by the tailwinds, we see many opportunities for growth in the Aalberts playing field, where we are accelerating semicon leading edge technologies, bringing eco-friendly buildings to life and transforming sustainable industries.

sustainability for all stakeholders

tailwinds

we are driven by four global tailwinds, prompting structural shifts in our industries. Driven by the tailwinds, we see many opportunities for growth in the Aalberts playing field, where we are accelerating semicon leading edge technologies, bringing eco-friendly buildings to life and transforming sustainable industries.

urbanization

strong need for comfortable and healthy buildings, sustainable transportation and connectivity

technology acceleration

exponential need for AI computing power, smart buildings, industry 4.0

reshoring

regionalization of critical manufacturing drives need for supply chain proximity

decarbonization

growing demand for energy efficiency and sustainable, lightweight and durable solutions

our playing field

realizing social and environmental impact in our end markets

the most sustainable ball valve on the market?

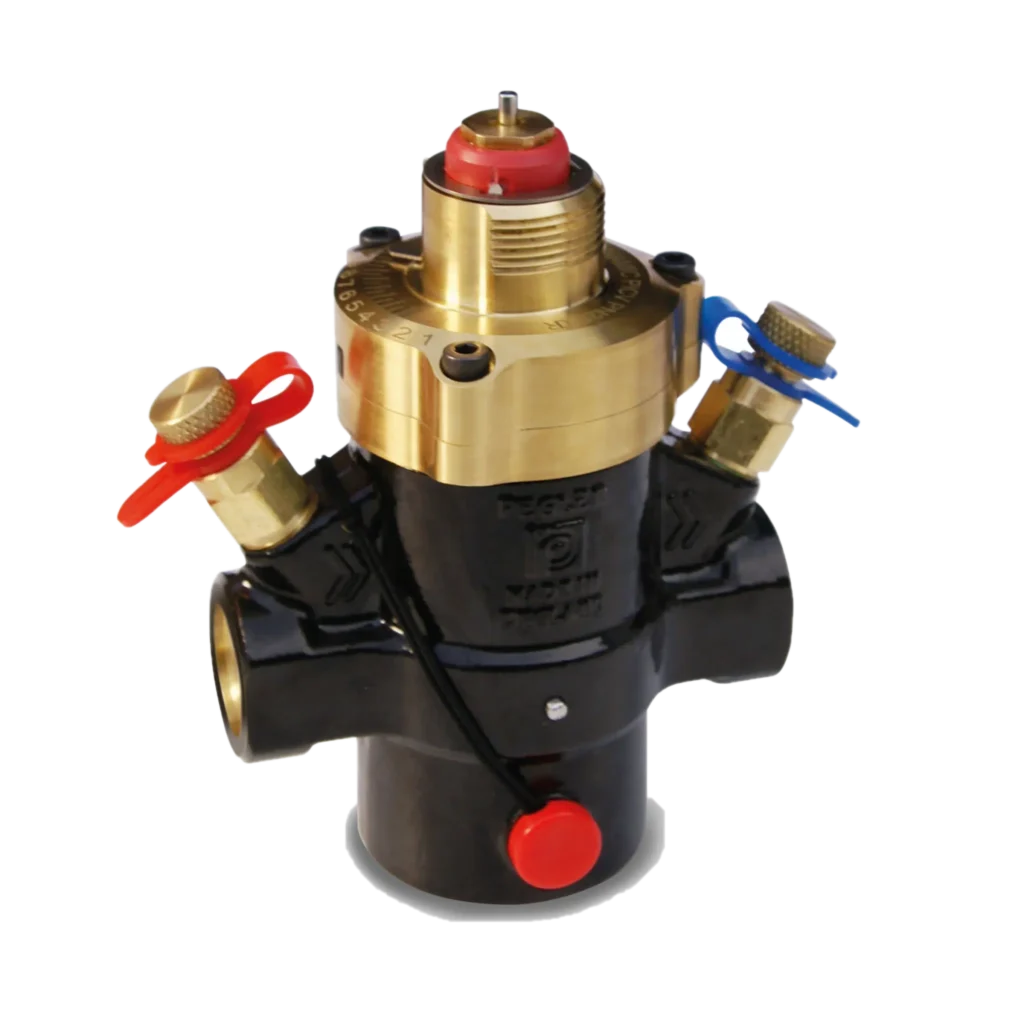

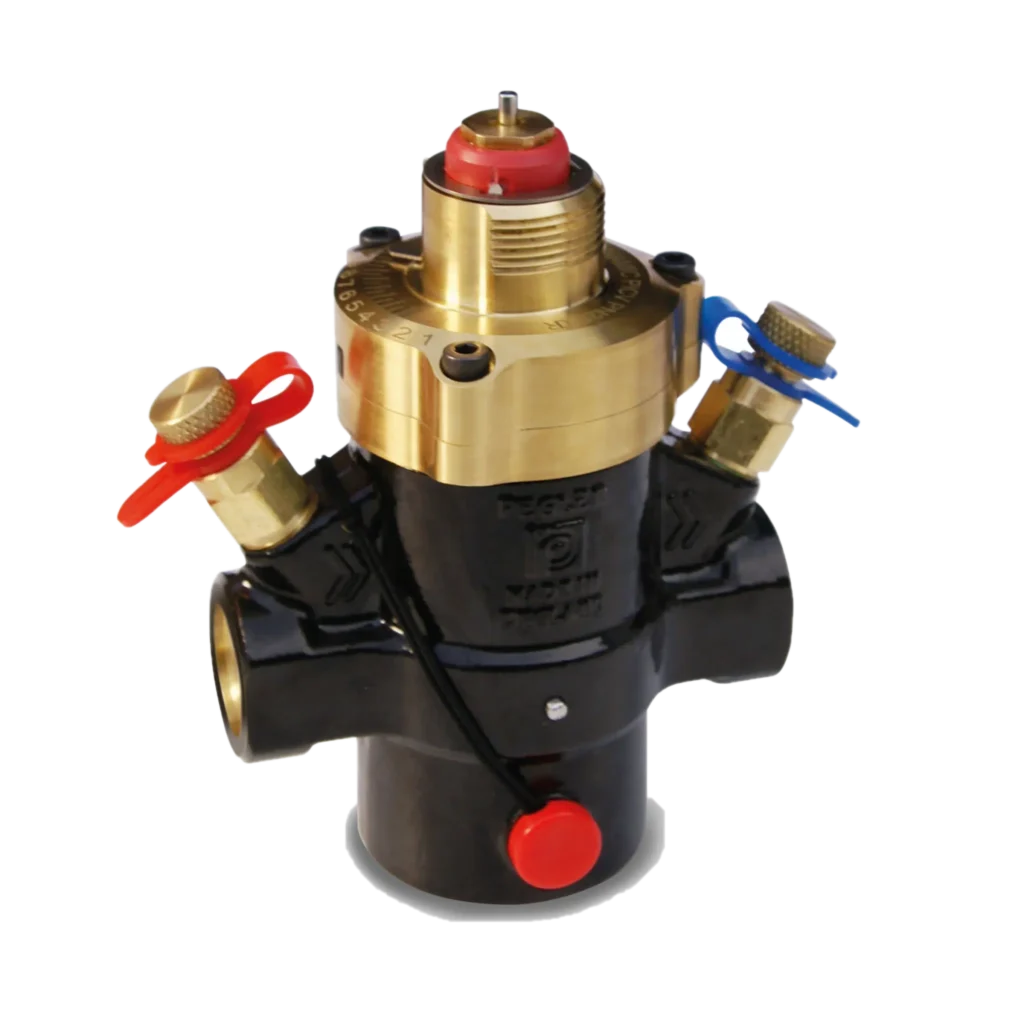

how does the Apollo PICV deliver comfort while cutting energy use?

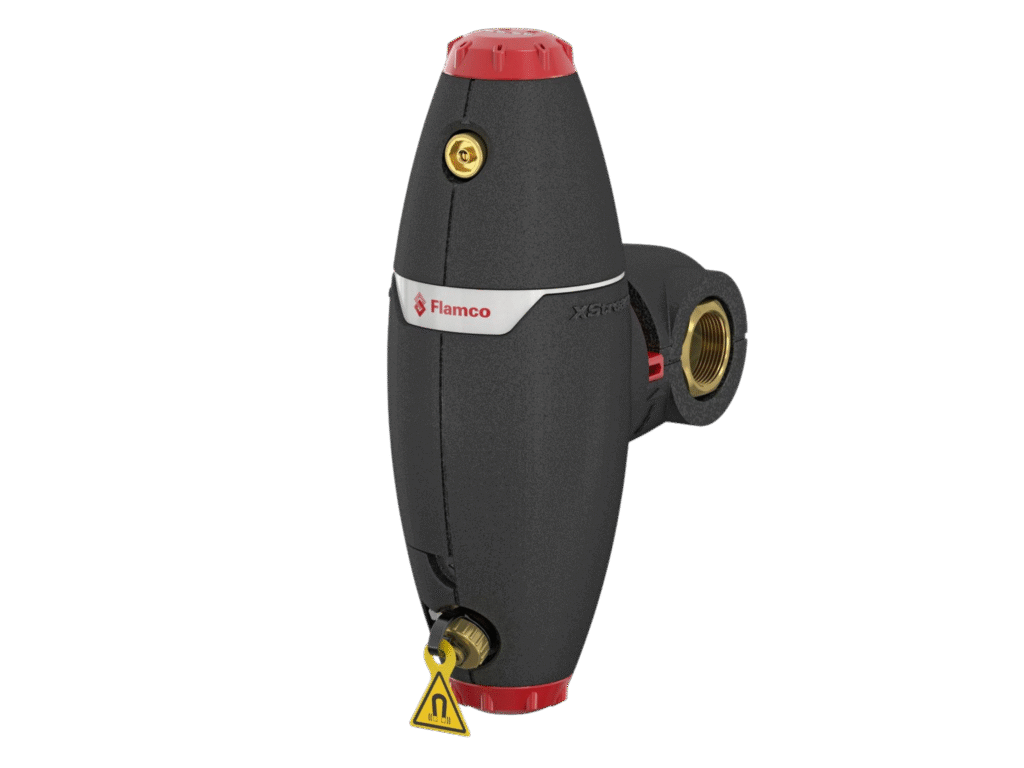

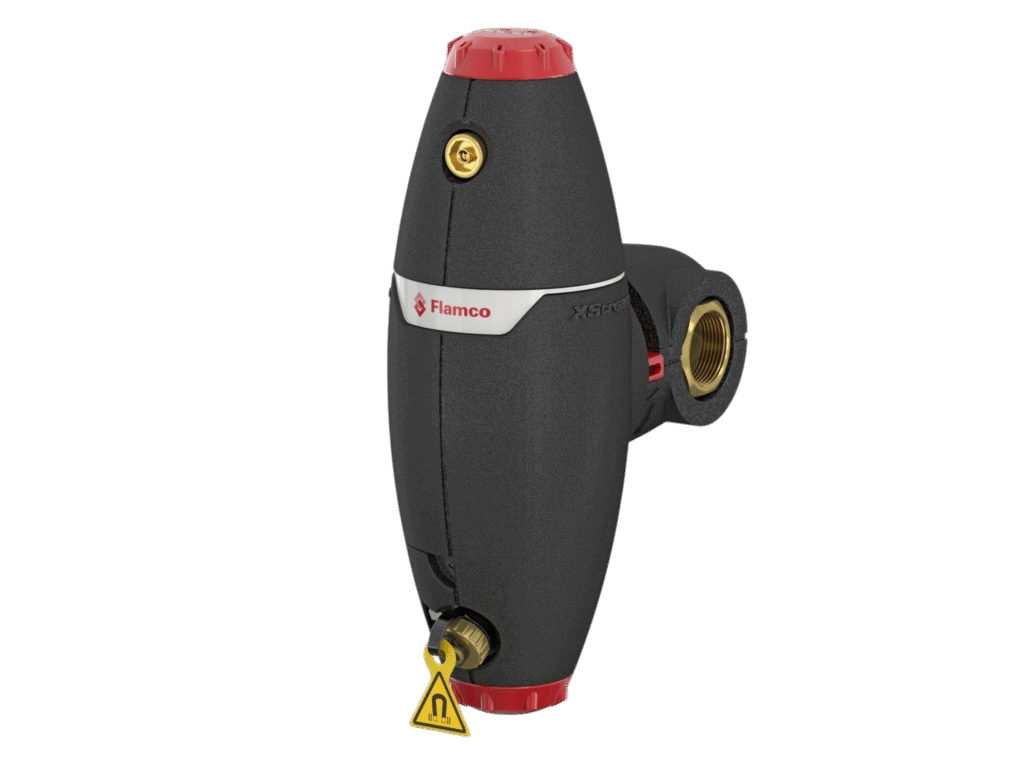

can air and dirt separators really boost energy efficiency?

the most sustainable valve on the market?

designed to cut flow resistance, emissions, and heat loss at every stage.

The Apollo FullFlow valve delivers a new standard in sustainable HVAC system design. Its full-bore construction minimizes pressure losses, cutting pump energy use significantly—an especially critical advantage in today’s complex heating and cooling networks. The valve’s compact structure and availability in both low and high spindle designs make it easy to insulate, reducing heat loss and associated lifecycle emissions. Unlike traditional valves with multiple materials, the Apollo FullFlow is built from stainless or electro-galvanized steel to match piping, preventing galvanic corrosion and extending service life.

On the production side, the design is radically streamlined: 50% fewer manufacturing steps, 26% fewer components, and a 97% reduction in welding energy compared to legacy valve types. This means a lighter, more resource-efficient product that performs without compromise. Apollo valves now also carry Environmental Product Declarations (EPDs) for stainless steel models, supporting transparency and responsible sourcing. Designed for digital workflows, the entire product range is available in MagiCAD Cloud, enabling HVAC engineers to optimize energy use and reduce material waste through accurate system modeling. Combined with a commitment to carbon footprint reduction across its operations, the Apollo FullFlow represents the next generation of energy-smart, climate-conscious valve technology.

can smarter balancing make your system more sustainable?

a compact valve that reduces energy use, water waste, and material complexity.

The Apollo ProFlow 1600 PICV is built to improve both system performance and environmental impact. By combining flushing, isolation, and pressure-independent flow control in a single valve, it reduces the need for multiple components—cutting raw material use and embodied carbon. Its bypass configuration allows full-bore flushing without removing the cartridge, reducing water waste, installation time, and early system inefficiencies.

Once commissioned, the valve ensures precise, pressure-independent flow control, improving energy efficiency and pump performance across the building. With no need for an inline ball valve, material use and leak points are further minimized. Service is streamlined with hot-swappable cartridges, integrated test points, and a visible setting indicator—reducing maintenance time, water loss, and service trips.

The Apollo ProFlow 1600 isn’t just a balancing valve—it’s a sustainable design choice that supports long-term energy savings, fewer emissions, and smarter system operation.

can air and dirt separators really boost energy efficiency?

XStream air and dirt separators deliver up to 15% energy savings and longer system life

With a strong need for efficient heating systems, Aalberts plays an essential role. We engineer mission-critical components for HVAC systems, combining established principles with new technologies. Our XStream series separate air and dirt particles from water in any kind of heating system: from small domestic use to large commercial and industrial applications. With unique ECO/MAX modes, our sustainable separators ensure lower energy consumption, less wear and tear, fewer breakdowns, a longer lifespan and thus a higher efficiency of heating and cooling installations.

So, how does it all match? As the demand for energy efficient products rises, we cover a broad spectrum of mission-critical building technology systems that make residential, commercial and industrial buildings eco-friendly. Realising up to 15% energy savings in heating systems, our sustainable air and dirt separators help homeowners and occupants to realise energy efficiency and to keep the planet in good shape.

themes to move sustainability forward

realizing positive impact with our mission critical technologies

we're committed to

play our role in achieving the Sustainable Development Goals

We commit to play our role in achieving the SDGs. With our mission-critical technologies, we accelerate unique positions with high growth potential and sustainable impact. Our social and environmental impact is reflected in our SDG rate: already 70% of our revenue contributes to those subgoals of the SDGs that are material to us. Our target is to maintain an SDG rate above 70%, while executing our growth agenda.

We aim to realize impact with our technologies as follows:

• SDG 6: Aalberts contributes to the hygienic distribution of water in buildings, by engineering solutions for safe and clean drinking water, water quality improvement and water efficiency

• SDG7: Aalberts contributes to the creation of energy savings in buildings and industry, by engineering technologies for heating and cooling systems, facilitate renewable energy installations and provide improved energy efficiency

• SDG 9: Aalberts contributes to the acceleration of technological breakthroughs in semicon, by delivering ultra-precision and ultra-clean liners, enabling accuracy and control and facilitating nanometer precision

• SDG12: Aalberts contributes to the lifetime extension and lightweight materials industry, by extending material lifetime and minimizing (hazardous) waste

mitigating climate change by taking responsibility for our footprint

we're committed to

be net zero carbon by 2050, or earlier

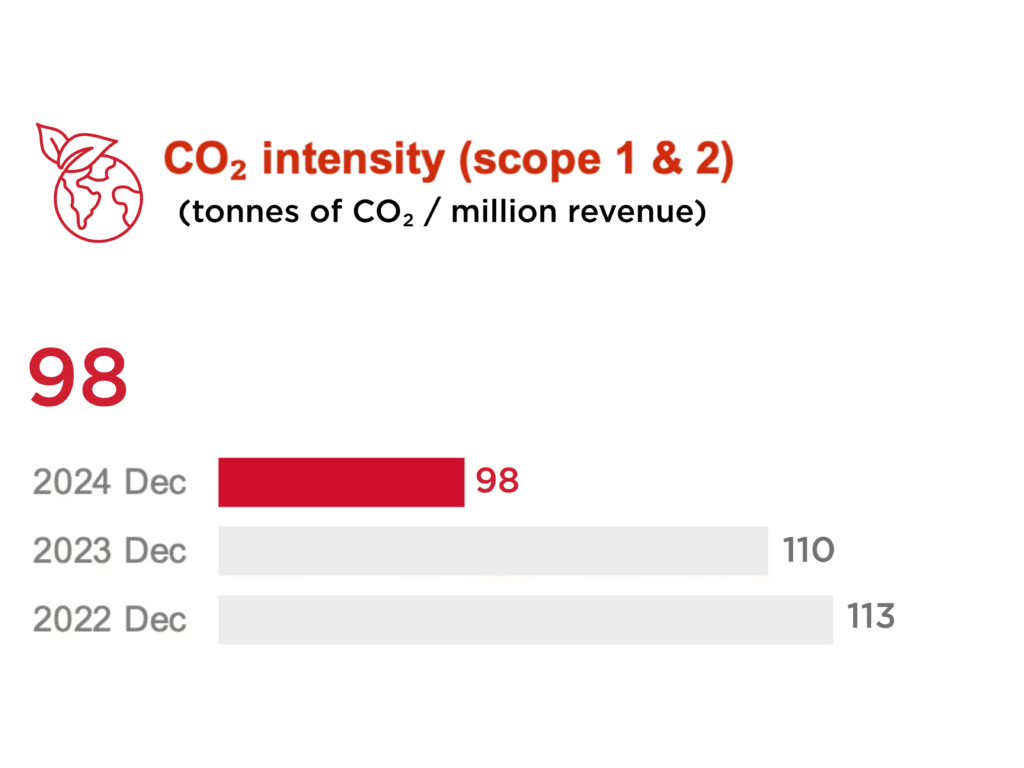

We commit to be net zero carbon by 2050, or earlier. Reducing CO₂ emissions through sustainable production impacts climate change effects and lowers operational costs by improving resource efficiency.

we act on six decarbonisation levers:

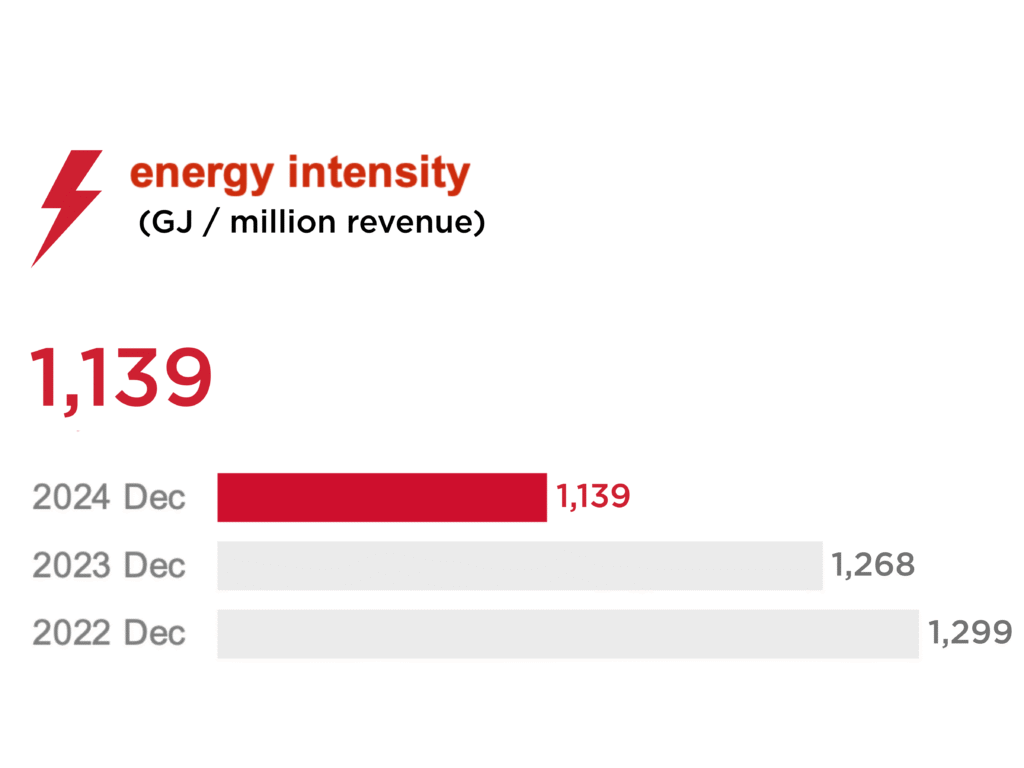

energy efficiency

we commit to implement energy efficiency and reduction measures

renewable energy

we commit to purchase or generate renewable energy

electrification

we commit to convert industrial processes to electricity-based power sources, where possible

smart product design

we commit to adjust product design to use less or low-carbon materials and ensure durability, reusability and recyclability of our products

circular solutions

we commit to reduce waste and recycle materials

value chain collaboration

we commit to engage our business partners to drive the sustainable transition across the value chain

For more information on our actions to reach net zero carbon by 2050 or earlier, please refer to our net zero carbon transition plan

making a material difference by look at material differently

we're committed to

use natural resources as efficient as possible

We commit to use natural resources as efficient as possible. To drive our commitment on circular economy throughout our value chain and counter resource depletion, we act as follows:

smart product design

- reduce material use: we use Life Cycle Assessments to minimise material usage in new product design

- prioritise low-carbon choices: we procure recycled and low-carbon materials to decrease our carbon footprin

- design for circularity: we engineer products built to last. We ensure durability during use, facilitate reusability and recycling at the end of life, maximising the longevity of material

act on circular solutions

- repair, reuse, refurbish: we collaborate with business partners to take back products and repair, reuse and refurbish to extend the lifetime of materials

- responsible resource use: we commit to proper waste handling to reduce our waste disposed and recycle raw materials in our operations

mitigating water scarcity by responsible water use

we're committed to

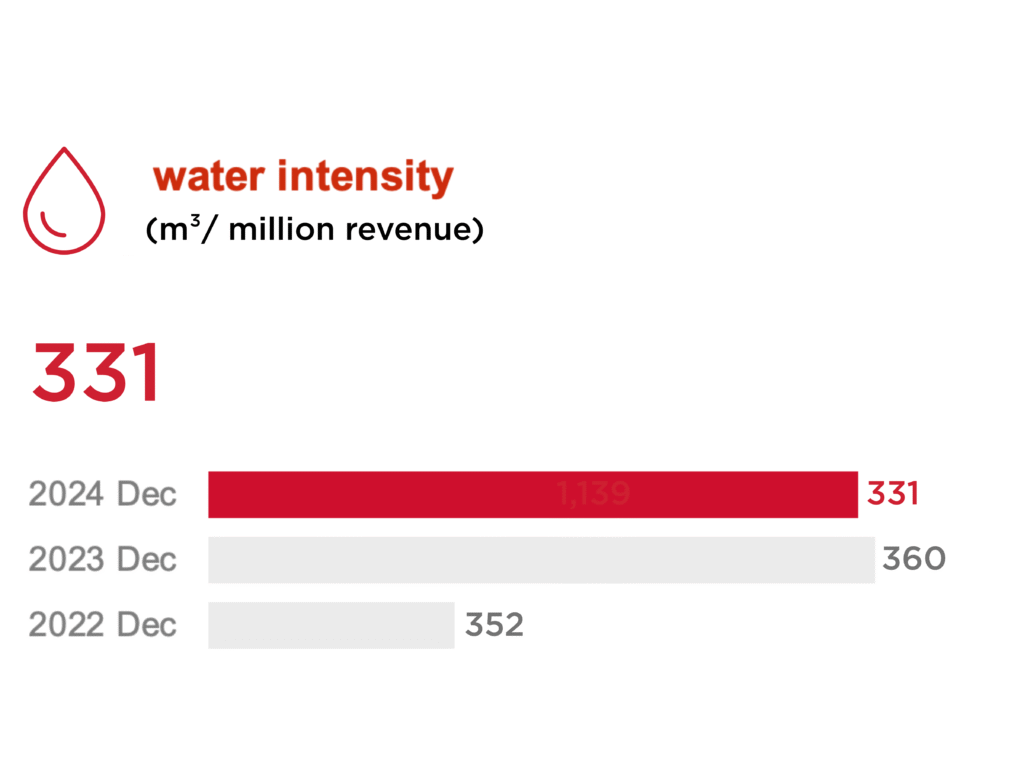

reduce water withdrawal and increase water treatment

We commit to reduce water withdrawal and increase water treatment. Although Aalberts’ operations do not require significant amounts of water for production or processing, we can play a role in mitigating this risk by optimising our water management. Aalberts seeks to promote responsible use of water throughout the company and reduce water intensity by:

• reducing water withdrawal: reducing the use of third party water, surface and ground water for sanitation and production purposes

• increasing water recycling: installing closed-loop water systems, reusing treated waste water and using rain water

• increasing water treatment: treating water in our own treatment stations and discharging purified process water to the water cycle

revealing the true environmental story behind our products

we're committed to

our environmental product declarations

Environmental product declarations (EPDs) provide transparent and scientifically based information about the environmental impact of a product throughout its lifecycle. EPDs provide verified information about a product’s carbon footprint, water usage and waste generation as well as other environmental impact factors. By comparing this with other EPDs our customers can make informed decisions, ensure their purchases have minimal impact on the environment and contribute to a sustainable future.

we're committed to

play our role in achieving the Sustainable Development Goals

We commit to play our role in achieving the SDGs. With our mission-critical technologies, we accelerate unique positions with high growth potential and sustainable impact. Our social and environmental impact is reflected in our SDG rate: already 70% of our revenue contributes to those subgoals of the SDGs that are material to us. Our target is to maintain an SDG rate above 70%, while executing our growth agenda.

We aim to realise impact with our technologies as follows:

• SDG 6: Aalberts contributes to the hygienic distribution of water in buildings, by engineering solutions for safe and clean drinking water, water quality improvement and water efficiency

• SDG7: Aalberts contributes to the creation of energy savings in buildings and industry, by engineering technologies for heating and cooling systems, facilitate renewable energy installations and provide improved energy efficiency

• SDG 9: Aalberts contributes to the acceleration of technological breakthroughs in semicon, by delivering ultra-precision and ultra-clean liners, enabling accuracy and control and facilitating nanometer precision

• SDG12: Aalberts contributes to the lifetime extension and lightweight materials industry, by extending material lifetime and minimising (hazardous) waste

we're committed to

be net zero carbon by 2050, or earlier

We commit to be net zero carbon by 2050, or earlier. Reducing CO₂ emissions through sustainable production impacts climate change effects and lowers operational costs by improving resource efficiency.

we act on six decarbonisation levers:

energy efficiency

we commit to implement energy efficiency and reduction measures

renewable energy

we commit to purchase or generate renewable energy

electrification

we commit to convert industrial processes to electricity-based power sources, where possible

smart product design

we commit to adjust product design to use less or low-carbon materials and ensure durability, reusability and recyclability of our products

circular solutions

we commit to reduce waste and recycle materials

value chain collaboration

we commit to engage our business partners to drive the sustainable transition across the value chain

For more information on our actions to reach net zero carbon by 2050 or earlier, please refer to our net zero carbon transition plan

we're committed to

use natural resources as efficient as possible

We commit to use natural resources as efficient as possible. To drive our commitment on circular economy throughout our value chain and counter resource depletion, we act as follows:

smart product design

- reduce material use: we use Life Cycle Assessments to minimise material usage in new product design

- prioritise low-carbon choices: we procure recycled and low-carbon materials to decrease our carbon footprin

- design for circularity: we engineer products built to last. We ensure durability during use, facilitate reusability and recycling at the end of life, maximising the longevity of material

act on circular solutions

- repair, reuse, refurbish: we collaborate with business partners to take back products and repair, reuse and refurbish to extend the lifetime of materials

- responsible resource use: we commit to proper waste handling to reduce our waste disposed and recycle raw materials in our operations

we're committed to

reduce water withdrawal and increase water treatment

We commit to reduce water withdrawal and increase water treatment. Although Aalberts’ operations do not require significant amounts of water for production or processing, we can play a role in mitigating this risk by optimising our water management. Aalberts seeks to promote responsible use of water throughout the company and reduce water intensity by:

• reducing water withdrawal: reducing the use of third party water, surface and ground water for sanitation and production purposes

• increasing water recycling: installing closed-loop water systems, reusing treated waste water and using rain water

• increasing water treatment: treating water in our own treatment stations and discharging purified process water to the water cycle

we listen, we act

recognized for the progress we make in various benchmarks

Given our lean and effective structure we only actively participate in the most leading sustainability ratings and benchmarks that are most useful for us and our stakeholders. We rather focus on performance improvement and managing our human, environmental and financial impact. However, the benchmarks help us assessing the topics that are most important to our stakeholders…

Sustainalytics

the approach of Sustainalytics is in line with Aalberts’ view on sustainable entrepreneurship: we are recognised for our no-nonsense approach and our reliable track record

Aalberts holds a medium risk score of 21.5 in 2024, coming from a medium risk score of 21.1 in 2019

CDP

the Carbon Disclosure Project helps us measuring and understanding our environmental impact and managing our risks and opportunities on climate change

Aalberts holds a CDP Management B rating for environmental stewardship in 2023, coming from a B- rating in 2018

CSA

the CSA approach of S&P Global (previously named Dow Jones Sustainability Index) is data driven and helps us to see what is of importance for our stakeholders and prioritise our efforts

Aalberts holds a 2024 CSA percentile ranking of 91, coming from a percentile ranking of 86 in 2018

MSCI

the MSCI ESG Rating assesses our exposure to and ability to manage long-term, industry-specific environmental, social, and governance (ESG) risks, providing a comprehensive evaluation of its sustainability performance

Aalberts holds an BBB rating in 2024, coming from a BBB rating in 2018

FTSE4GOOD

the FTSE4Good Index Series recognises companies that demonstrate good ESG practices, and serves as a tool for investors seeking to align their portfolios with responsible investment principles

Aalberts was confirmed as a constituent following the June 2024 Index review

sustainable numbers

downloads

driving change with people and technology

Lisa Phocas

sustainability director