Apollo PowerPress

Apollo PowerPress® is a state-of-the-art carbon steel press system designed for use with schedule 10 through 40 thick wall steel pipes. Available in sizes ranging from ½” to 4”, this system provides a reliable, efficient, and durable solution for various piping applications.

product line overview

Apollo PowerPress® fittings and valves are zinc-nickel coated for superior corrosion resistance and feature either an EPDM or HNBR sealing element. The system includes a unique Leak Before Press® feature, ensuring un-pressed fittings will visibly leak during low-pressure testing, and a patented visual control ring (VCR) that offers clear indication when a connection has been pressed.

key features

- leak before press® technology: ensures un-pressed fittings leak during low-pressure testing, providing immediate feedback.

- visual control ring (VCR): patented design with break-away tabs and color coding for easy identification of sealing element type.

- corrosion resistance: zinc-nickel coating provides excellent durability against corrosion.

- enhanced connection security: smart teeth on the stainless steel gripping ring ensure maximum connection integrity.

- increased cup depths: better seat and tighter seal for straighter pipe runs.

- protective shipping cap: color-coded to protect VCR and fitting ends during shipping.

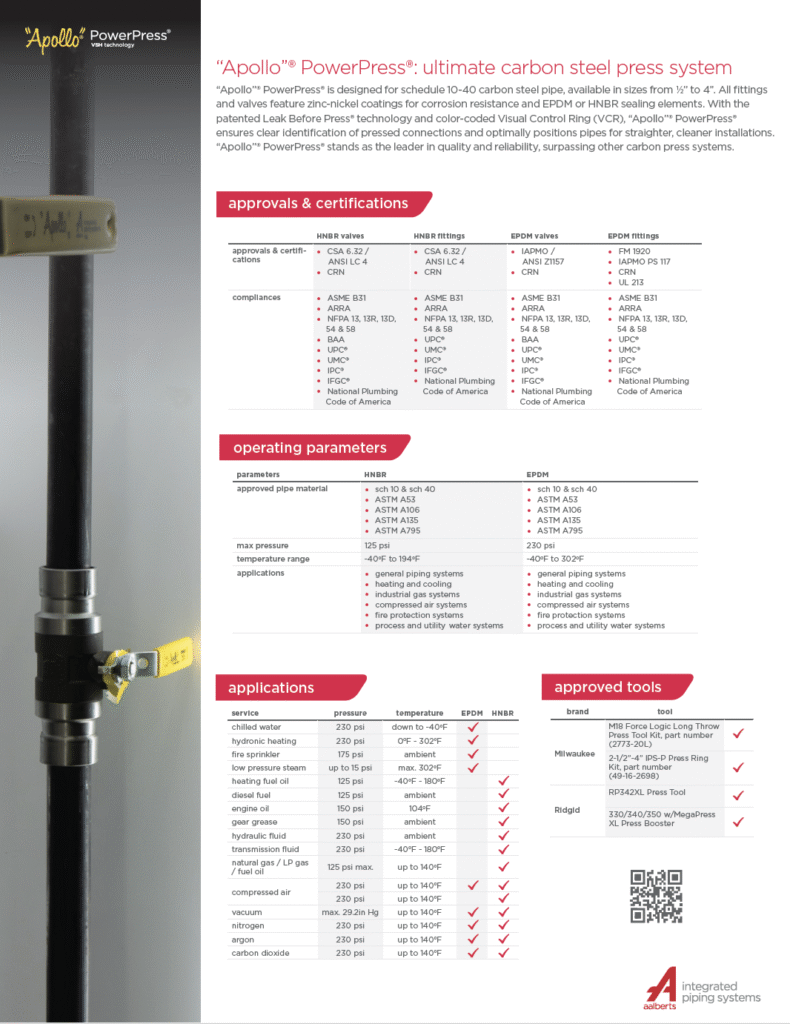

operating parameters

EPDM sealing element:

- max operating pressure: 230 PSI

- operating temperature: -40°F to 302°F

HNBR sealing element:

- max operating pressure: 150 PSI

- operating temperature: -40°F to 194°F

approvals and certifications

Apollo PowerPress® is compliant with:

- uniform plumbing code (UPC®)

- uniform mechanical code (UMC®)

- national plumbing code of Canada

- international plumbing code (IPC®)

- international fuel gas code (IFGC®)

- ASME B31

- NFPA 13, 13D & 13R, 54 & 58

product range

Apollo PowerPress® offers a comprehensive range of fittings and valves, including:

- elbows: 90° and 45° elbows in various sizes.

- tees: standard and reducing outlet tees.

- couplings: standard and no-stop couplings.

- adapters: male and female thread adapters.

- flanges: ANSI class 150 flange adapters.

- unions: standard and female unions.

- caps: tube caps for sealing pipe ends.

applications

Apollo PowerPress® is suitable for a variety of applications, including:

- chilled water

- hydronic heating

- fire sprinkler systems

- low-pressure steam

- compressed air

- fuel gas

conclusion

Apollo PowerPress® sets the standard in the industry for carbon steel press systems with its innovative features, high reliability, and wide range of applications. This all-in-one piping solution ensures ease of installation, maximum security, and excellent performance, making it the preferred choice for professionals in the field.